Objectives:

- Achievement of novel soil conditioners aiming at a cost-efficient improvement of key soil features, including water dynamics, fertility and soil physical properties, with highest environmental standards.

- Develop, test and achieve novel groundcovers, meeting the following standards: cost-efficiency, based on low-cost raw materials, locally produced, preferably built with waste materials and with proven physical stability. The novel techniques must be either 100% biodegradable without leading to negative impact on the environment or not degradable at all, so that they could be used several times.

Tasks:

The novel techniques to be developed and evaluated must improve the cost-efficiency of current best-available techniques for soil conditioners and soil covers. It is fundamental to reach an adequate balance between water infiltration, mitigation of soil water evaporation and transpiration. The techniques should allow water from light rainfall episodes to reach the ground. Also achieved a satisfactory balance of absorption and reflection of UV and IR radiation should be achieved resulting in an optimal soil temperature.

In this first preparatory task, all these requirements were analysed and taken into account for the elaboration of the different novel soil-cover types and novel soil conditioner, leading to the fine-tuning of the product development in Task 2.2.

Based on the previous analysis each SME partner DTC, La Zeloise, Ecorub, Terracottem has optimised and developed a specific product to be evaluated in the afforestation test field trials. Material description and base properties are defined for each individual product.

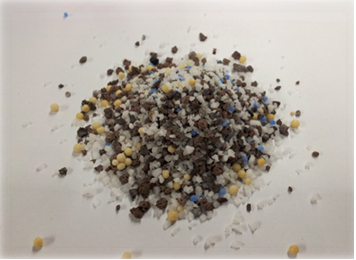

A . Novel acrylamide-free soil conditioner: TCUplus® by TerraCottem Internacional

Although it has been proven that the Terracottem soil-conditioner TCU® enhances drastically the growth of plants and has no negative ecological effects, there is still a concern in the market, since the material is partially based on polyacrylamide chemistry. The polymer is perfectly safe but the monomer used in the production has some ecological drawbacks.

An intensive reformulation program was started to develop and alternative polyacrylamide-free soil conditioner that still retains or further improves the properties of the reference Terracottem TCU. After primary chemical analysis a dozen formulations were tested in fast bio-screening trials in green-houses to assess the performance as soil-conditioner.

Based on these results a final optimised formulation encoded TCUplus was selected for upscaling trials and supplied for the further afforestation field trials.

This final product encoded TCUplus was produced in appropriate amounts for the planned Sustaffor field trials and after quality controls sent to the coordinator CTFC.

Novel soil conditioner TCUplus

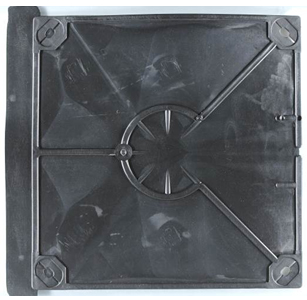

B. Biodegradable groundcovers via injection moulding technology by DTC

For the development of novel groundcover system a first route followed is by injection moulding technology. Instead of using petrochemical based polymers such as PP or PE biopolymers were used. Several polymer types including PLA, PHA, Starch based and blends of them were evaluated, both for processability properties and intrinsic properties of the injection moulded parts including, flexibility, strength, impact resistance.

Finally a special designed biopolymer blend was defined for the final production trials offering the best performance both in processability and in properties.

A special mould was designed in order to produce in a single step a groundcover of 40 by 40 cm, specially adapted to facilitate In the future alternative ground-cover sizes could be defined. It is also possible by combing 4 small groundcovers to create large groundcover of 80 by 80 cm.

Injection moulded groundcover plate (40×40 cm)

As an alternative for this first injection moulded groundcover plate, a support structure is injection moulded directly on a biodegradable biopolymer film. Although the film part will have a lower durability then the injection moulded part, the advantages are that a lightweight and economic structure is obtained, that still can easily be installed and fixed to the ground due to the solid rim.

Along with the groundcovers also biopolymer based fixation pins are supplied to keep the groundcovers in place in the fields. As such a 100% biodegradable groundcover, easy to install and with a 100% inhibition of the weed growth can be obtained.

Groundcover obtained via injection moulding a support structure on a biopolymer film (40×40 cm)

Bio-based fixation pins to be used in combination with previous plates.

C. Bioresin treated natural fibres-based groundcovers by La Zeloise

In an alternative approach also natural fibre based groundcovers could be used. Such ground covers based on especially Jute fibres are commercially available and can already be used as groundcover. However their durability, particularly in warm and humid environments, is limited.

La Zeloise has used a novel approach by applying a bioresin that acts as a preservative and extends the lifetime of the product. The bioresin formulation along with the application process required further optimisation to get optimal performance of the groundcover. Also the impact on mechanical properties and stiffness was examined and brought under control by selection of formulation, process methodology and applied concentration. Due to the raised stiffness of the fabric, the groundcovers are easier to handle during installation around the tree. The materials are not only fully biobased but offer as well a full biodegradability after an extended lifetime of about 3 to 5 years. The bioresin treated fabric show also improved properties against flammability.

Since production is performed in full width via roll to roll impregnation, drying, curing groundcovers can be produced in a flexible way in all varieties of sizes. For the field trials groundcovers of 40 by 40 cm and 80 by 80 cm are supplied and installed.

Groundcovers based on woven jutecloth; a) reference jutecloth, b) bioresin treated jute cloth

In the future some further improvements or alternative versions of this type of groundcovers can be expected.

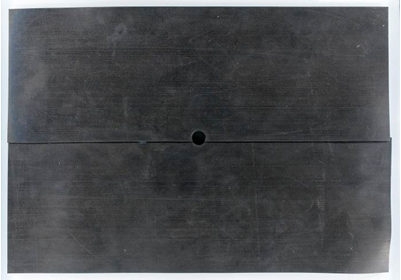

D. Recycled rubber-based groundcovers by EcoRub

Instead of using biobased materials also the use of recycled materials can offer large ecological benefits. Ecorub produces a range of different articles based recycled rubber offering a second life to materials that normally will be burned or deposited.

Based on their technology they developed a rubber mat that can be used as groundcover. The material is not biodegradable but instead it can be used for a long time in multiple plantation operations. The material offer possibilities to be supplied in different thickness and sizes. For the Sustaffor project a thickness of 1.5 mm was selected offering an appropriate balance in strength, weight, handling and installation possibilities. For the project either 40 by 40 cm or 80 by 80 cm groundcovers were produced. Materials are foreseen of a central hole and a slit to ease the groundcover installation around the tree. The larger size groundcovers are assembled from two rectangular pieces of 40 by 80 cm glued together. In the future this can be revised if production capacity for rubber mats with a higher width becomes available.

Groundcover made with recycled rubber mat. The sample produced for the field trials consists on two rubber stripes (40×20 cm) glued on the small overlap and with a central hole for the tree stem

During Work Package 2 all novel techniques (1 soil conditioner and 4 groundcovers) were produced and supplied for their evaluation at the field trials described in Work Package 3 and the laboratory tests of Work Package 5. The performance of the various techniques will be analysed in comparison with reference techniques, which are those currently applied. Based on the results of these trials, a further optimisation towards final commercial products is still feasible.